-

Latest Blog

-

Latest News

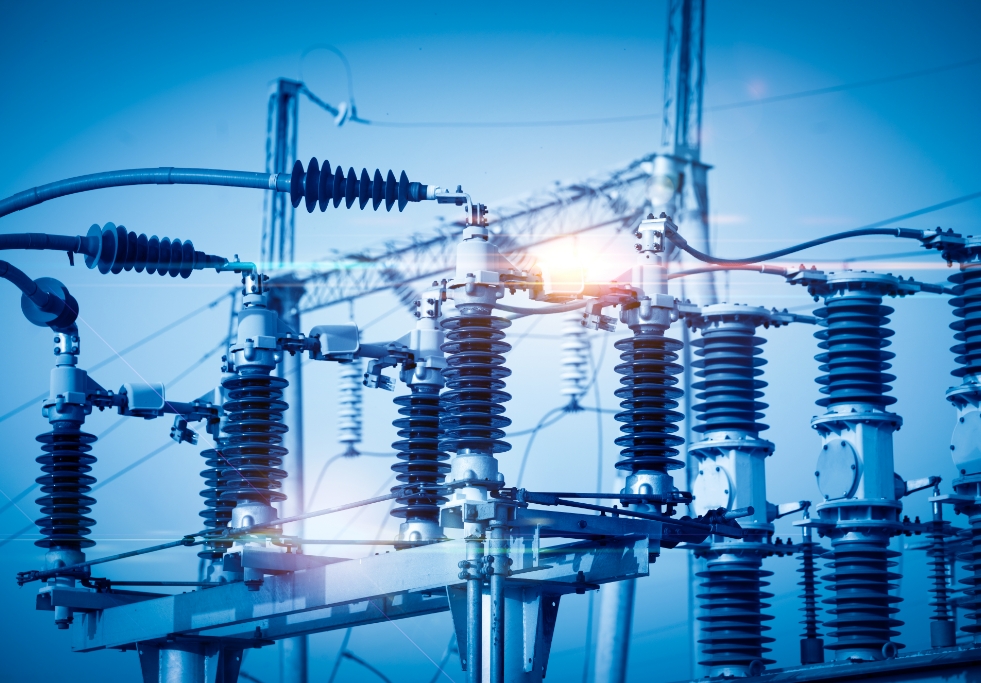

A Type Tested Panel, or TTP for short, is an essential component of electrical power distribution systems. It is designed to ensure the safe and reliable operation of the system, even under the most challenging conditions. In this blog post, we will explore the importance of TTPs, their design, and testing procedures.

A Type Tested Panel is a term used to describe a complete assembly of switchgear, control gear, and protective devices that have undergone a series of rigorous tests to ensure their safety and reliability. TTPs are used in a wide range of applications, including power generation, transmission, and distribution.

TTPs are designed to meet strict standards, such as IEC 61439-1 and IEC 61439-2. These standards define the requirements for low-voltage switchgear and control gear assemblies, including TTPs. The design and construction of TTPs are critical to ensure the safe and reliable operation of electrical power systems.

TTPs are essential for ensuring the safe and reliable operation of electrical power systems. They are used to protect personnel and equipment from electrical faults, such as short circuits and overloads. TTPs also provide control and monitoring of electrical systems, ensuring that they operate within safe limits.

In addition, TTPs are designed to be modular, which allows for easy installation, maintenance, and modification. This modular design makes TTPs a cost-effective solution for power system design and construction.

The design of a TTP begins with the selection of the appropriate components, such as circuit breakers, contactors, and fuses. These components must be compatible with each other and with the system in which they will be used.

The TTP’s enclosure is also an essential component of the design. The enclosure must be made of materials that are durable, corrosion-resistant, and able to withstand harsh environmental conditions. The enclosure must also be designed to provide adequate ventilation and cooling to prevent the buildup of heat, which can damage the components inside.

Once a TTP has been designed and constructed, it must undergo a series of rigorous tests to ensure its safety and reliability. The tests are performed in accordance with IEC 61439-1 and IEC 61439-2.

● Verification of the design and construction of the TTP

● Verification of the compatibility of the components

● Verification of the protection provided by the TTP

● Verification of the thermal performance of the TTP

● Verification of the electrical performance of the TTP

● After the TTP has passed all of the tests, it is certified as safe and reliable and can be put into service.

Type Tested Panels are essential components of electrical power systems. They ensure the safe and reliable operation of the system, protect personnel and equipment from electrical faults, and provide control and monitoring of electrical systems. The design and construction of TTPs are critical to their performance, and rigorous testing is necessary to ensure their safety and reliability. If you are designing or installing an electrical power system, be sure to include a Type Tested Panel in your plans.